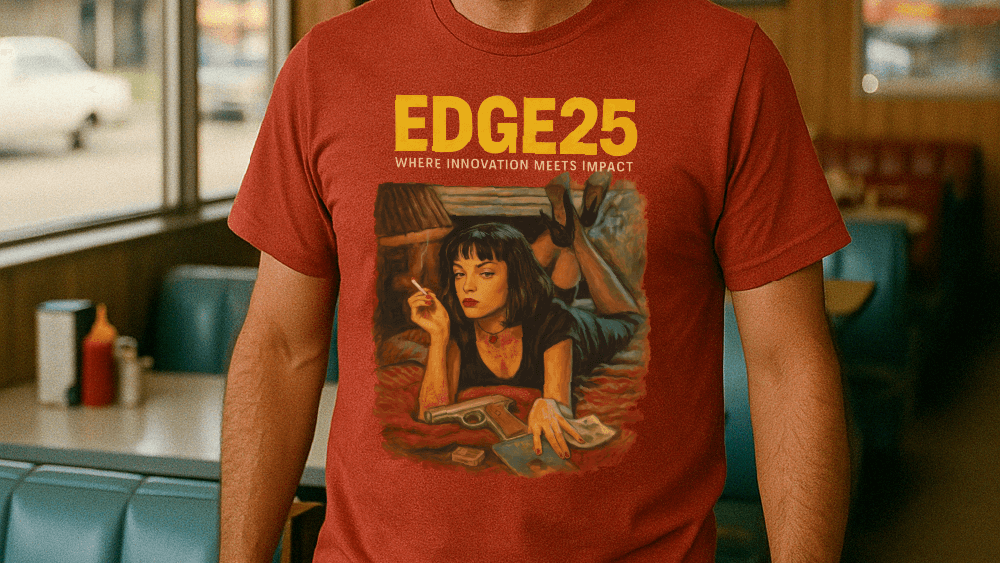

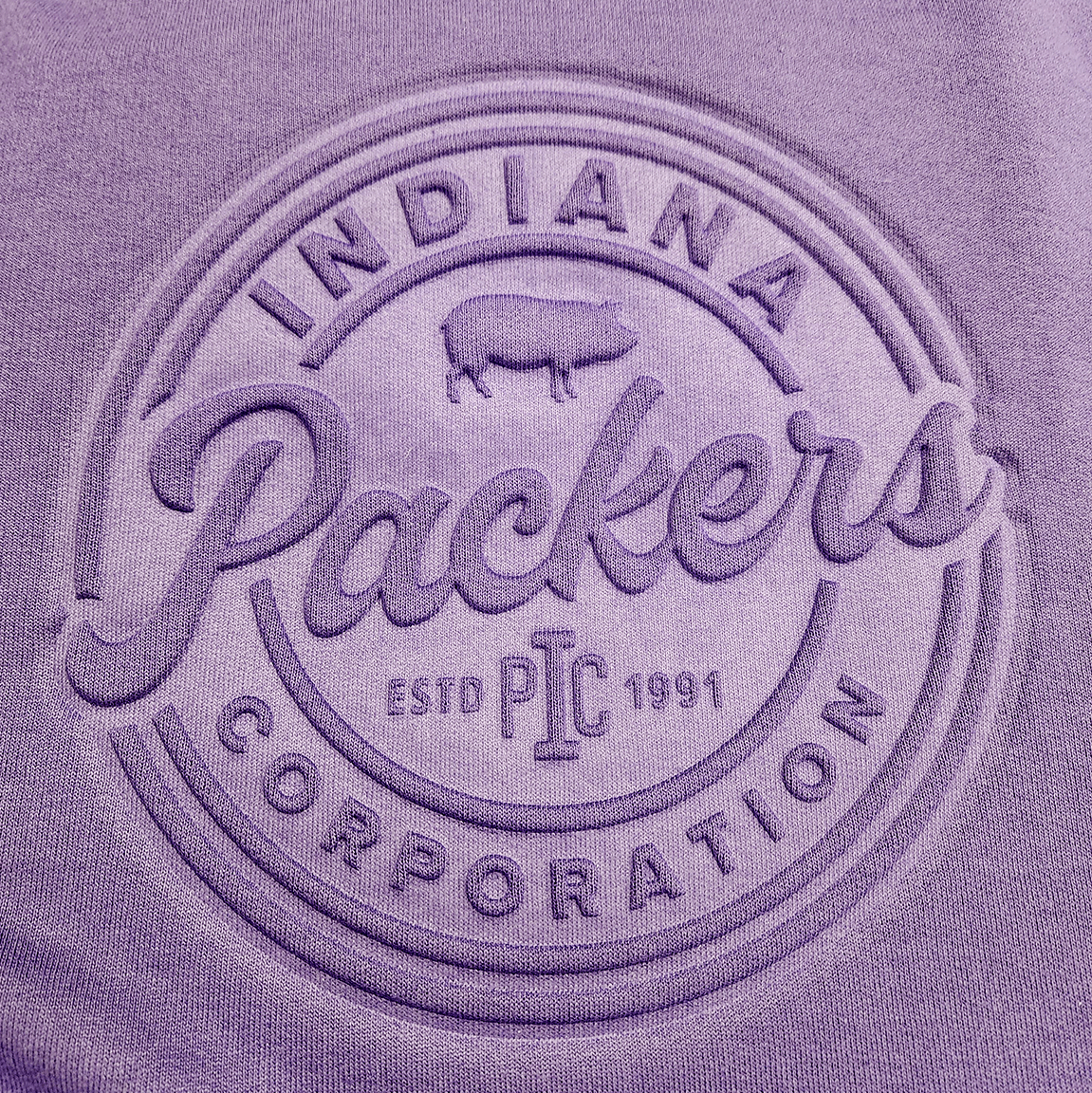

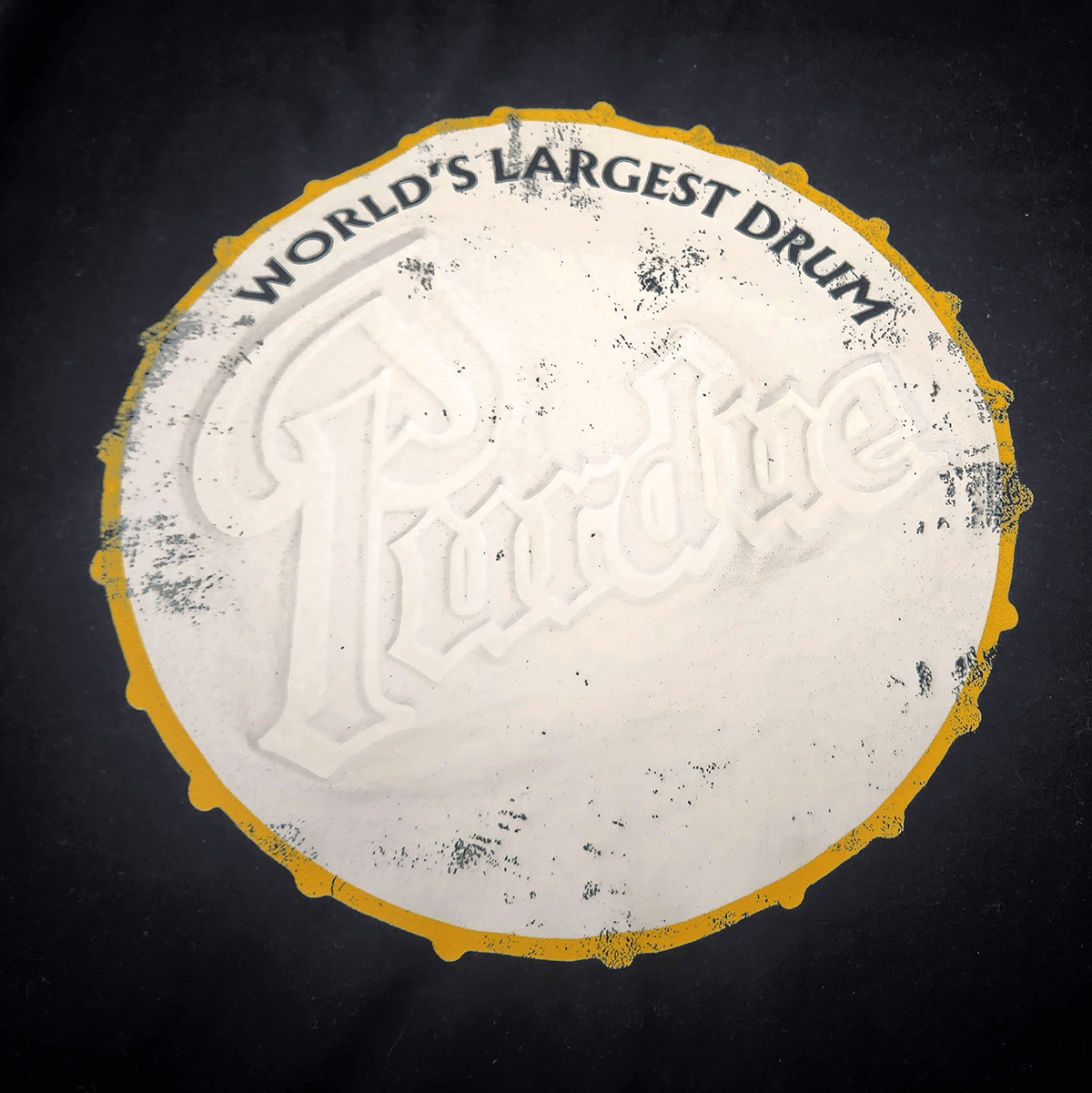

Apparel Embossing

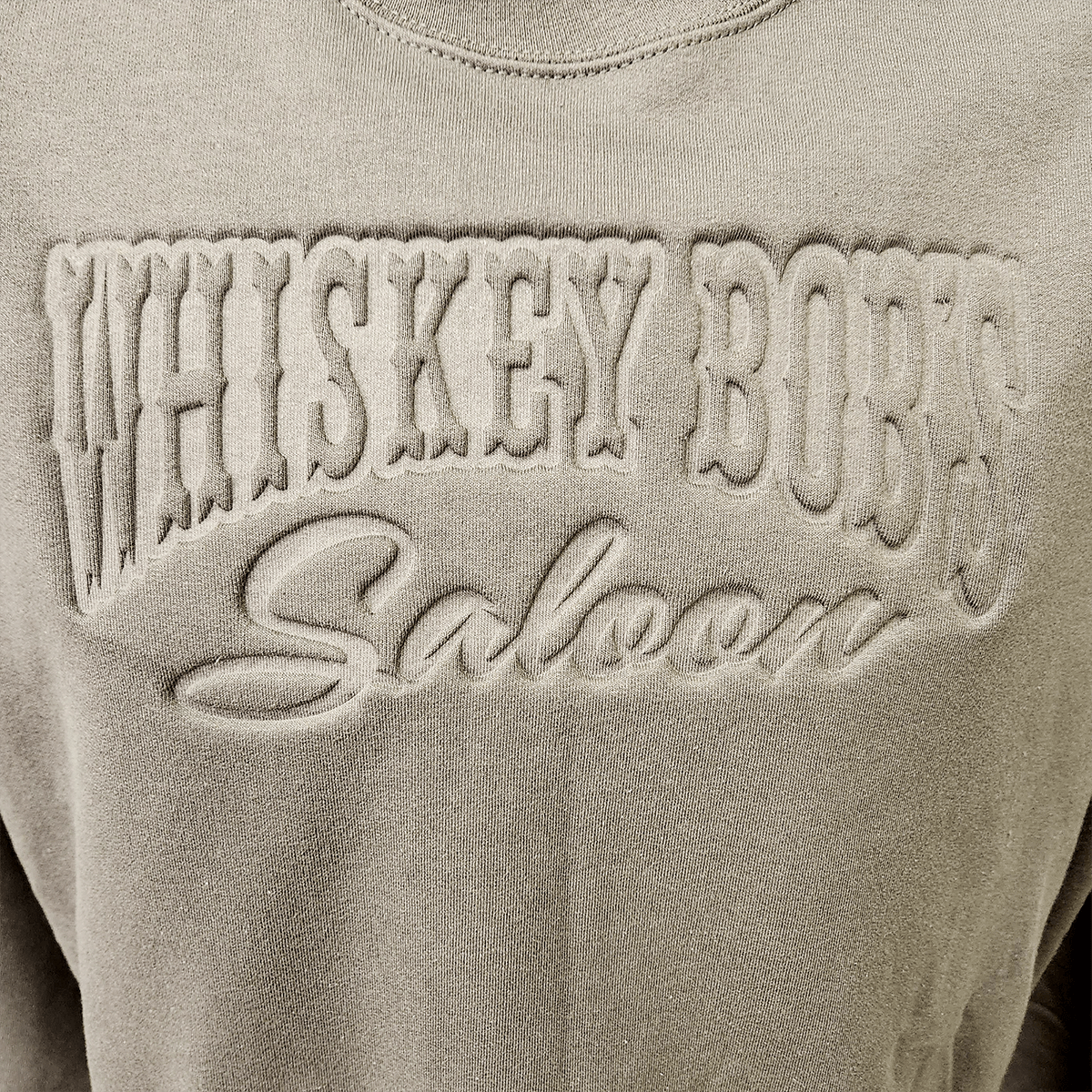

I learned to operate an apparel embosser and got comfortable designing for its specific depth, texture, and limitations. I focused on clean, high-impact embossed logos and paid close attention to line weight, clarity, and how each design would translate into fabric.

As I spent more time with the machine, I started experimenting with mixing embossing and digital print—creating a hybrid look that added color and dimensional detail. It became a modern, retail-ready effect and a good example of how quickly I can adapt to new production methods and turn them into something visually unique.

UV Printed Products

I operated a UV printer and designed artwork that played to its strengths—sharp detail, vibrant color, and precise, repeatable output. I created everything from hat patches and leather accents to custom golf balls and accessories, learning how each material reacted to being UV printed on and adjusting my designs for the best results.

While working with the machine, I also helped identify a new product opportunity: UV-printed hat patches. They became a strong alternative for artwork that was too detailed for embroidery—clean, durable, and premium looking. It’s a solid example of combining production knowledge with problem-solving to expand our product offerings.

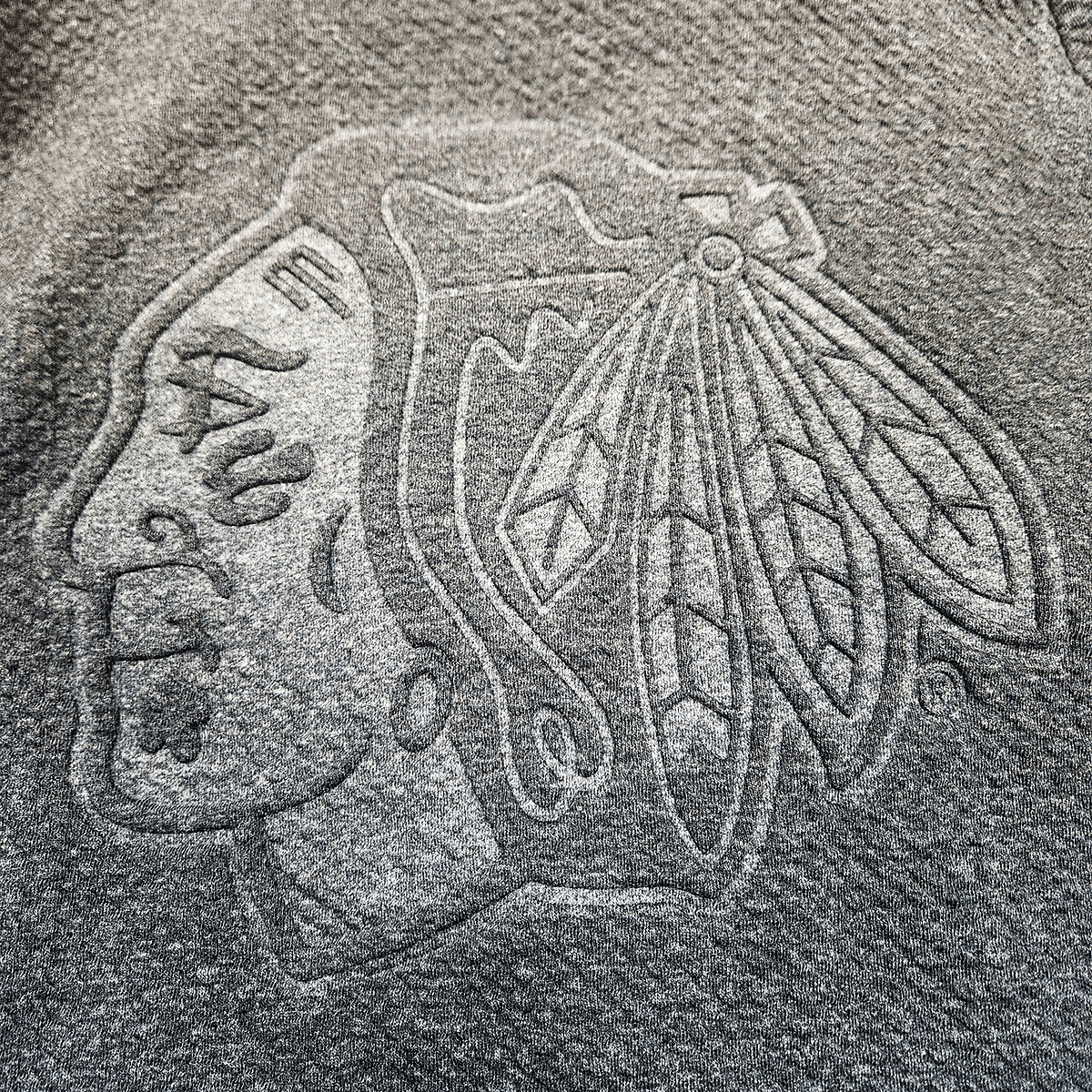

Lasered Apparel

I learned to operate an apparel laser and quickly understood how different fabrics respond to etching, shading, and varying burn depths. That let me create clean, detailed logos and patterns across performance wear, fleece, and hats.

As I grew in experience, I started combining laser etching with embroidery—using the laser for textured backgrounds, cut-in details, and precise placement guides that elevated the final stitched pieces. This opened up new product options and shows how I use new equipment creatively to build fresh, unique designs.

Drinkware Printed Products

For our 360° cylindrical printer, I created artwork specifically for full wraparound prints. I didn’t operate the machine directly, but I focused on building seamless layouts, clean edges, and graphics that stayed clear from every viewing angle. Designing for curvature and distortion was a key part of the process.

I developed wraps for glassware, tumblers, and bottles, tailoring each design to the product’s size and material. Working closely with the print operators helped fine-tune color, placement, and readiness so the machine could produce fast, consistent, high-quality results. It strengthened my ability to design for unique production constraints and support efficient workflows.